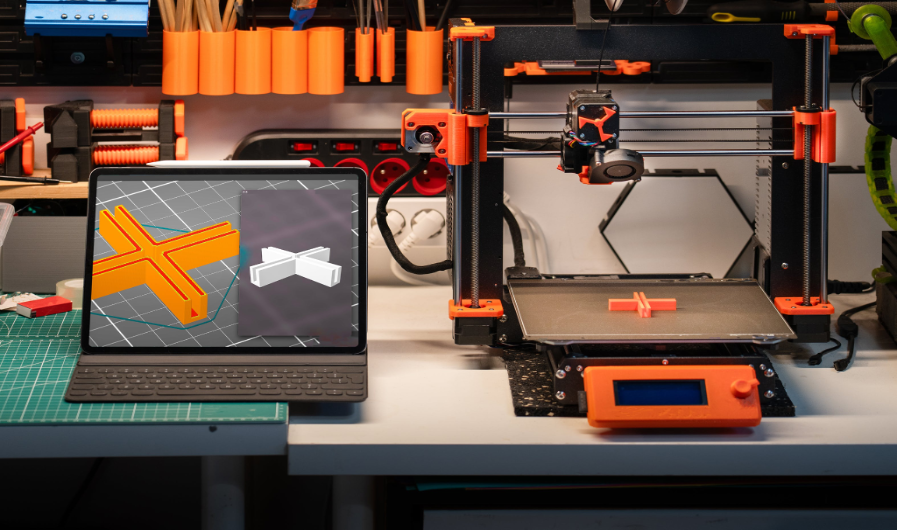

In an era where innovation drives progress, the fusion of 3D printing with automotive design stands as a beacon of technological evolution. This transformative pairing has not just reshaped how vehicles are conceptualized and manufactured, but it also signals a significant shift in design paradigms. The journey of 3D printing in automotive design is a tale of ingenuity and relentless pursuit of efficiency, where intricate layers of material forge the future of transportation.

3D printing, initially perceived as a tool for hobbyists and designers, has rapidly ascended to become a cornerstone in automotive design. The technology’s journey from rudimentary prototypes to complex, functional parts illustrates a remarkable leap in innovation. This evolution is mirrored in how automakers embrace 3D printing, evolving from cautious experimentation to full-scale integration in their design processes.

The landscape of 3D printing in automotive design is diverse, encompassing a range of technologies each with unique capabilities. These technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), are instrumental in bringing intricate automotive designs to life. They offer a level of precision and customization previously unattainable, propelling automotive design into a new realm of possibilities.

What Is 3D Printing and How Does It Work in Automotive Design?

3D printing, a marvel of modern technology, operates by layering materials to create objects from digital models. In automotive design, this translates to an unparalleled freedom in creating complex, lightweight, and durable components. The technology circumvents traditional manufacturing constraints, allowing designers to reimagine the anatomy of vehicles.

Main 3D Printing Methods Used in Automotive Design

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

Each method brings its unique strengths to automotive design. FDM, known for its versatility, is ideal for prototyping and basic components. SLA, with its precision, caters to intricate designs requiring fine details. SLS stands out in creating durable and complex parts, essential for functional automotive components.

Why Is 3D Printing Transforming Automotive Design?

Customization Opportunities

3D printing is redefining the bounds of automotive customization, allowing for:

- Bespoke 3D printed parts tailored to specific needs

- Unique design features that showcase individuality

Rapid Prototyping

The speed at which prototypes can be developed and iterated with 3D printing accelerates the design process, fostering innovation and efficiency.

Cost-Effectiveness

3D printing introduces significant cost savings in design and manufacturing, reducing waste and streamlining production processes.

Enhanced Performance and Innovation

The technology has spurred performance improvements and innovative designs, contributing to lighter, more efficient, and aesthetically pleasing vehicles.

How Does 3D Printing Impact Automotive Manufacturing Processes?

3D printing’s integration into manufacturing processes marks a seismic shift in production workflows. It streamlines the creation of complex parts, reduces inventory needs, and allows for on-demand manufacturing.

Changes in Manufacturing Workflow:

- On-demand production capabilities

- Reduced inventory and storage requirements

- Enhanced supply chain efficiency

Advantages of 3D Printing in Automotive Design

- Reduced waste and environmental impact

- Shorter lead times for part production

Capability to create complex geometries unachievable through traditional methods

Challenges and Limitations of 3D Printing in Automotive Design

Despite its advantages, 3D printing faces challenges:

- Material limitations impacting durability and longevity

- Scale limitations in producing large components

Production speed constraints compared to traditional methods

Case Studies: Successful Applications of 3D Printing in Automotive Design

Several case studies illustrate 3D printing’s transformative impact on automotive design, showcasing innovation, efficiency, and enhanced performance.

The Future of 3D Printing in Automotive Design

Emerging Technologies and Materials

The horizon of 3D printing in automotive design is bright, with emerging technologies and materials set to further revolutionize the field.

Predictions for 3D Printing’s Role in Future Automotive Design

Speculative insights suggest an ever-growing role for 3D printing, with potential advancements shaping the future of automotive design in unprecedented ways.

Step-by-Step Guide to Implementing 3D Printing in Automotive Design

Implementing 3D printing in automotive design involves a series of strategic steps:

Assessing design requirements and compatibility with 3D printing

Selecting appropriate printing technology and materials

Integrating 3D printing into existing design and manufacturing processes

What Are the Environmental Impacts of 3D Printing in Automotive Design?

The environmental impacts of 3D printing in automotive design are twofold, presenting both challenges and opportunities for sustainability.

Legal and Safety Considerations in 3D Printing for Automotive Design

Navigating the legal and safety landscape is crucial, with regulations and standards evolving alongside the technology.

Educational and Skill Requirements for 3D Printing in Automotive Design

Professionals aspiring to excel in this field must equip themselves with a specific set of skills and educational backgrounds, aligning with the demands of this innovative technology.

The journey of 3D printing in automotive design is a testament to human ingenuity and the relentless pursuit of progress. As we stand on the cusp of a new era in automotive design, the role of 3D printing cannot be overstated. It is not just a tool or a process; it is the harbinger of a future where the limits of design and manufacturing are continually redefined, promising a road ahead filled with innovation, efficiency, and endless possibilities.